Commercial Restaurant Remodeling – The Typical Process

March 11, 2019

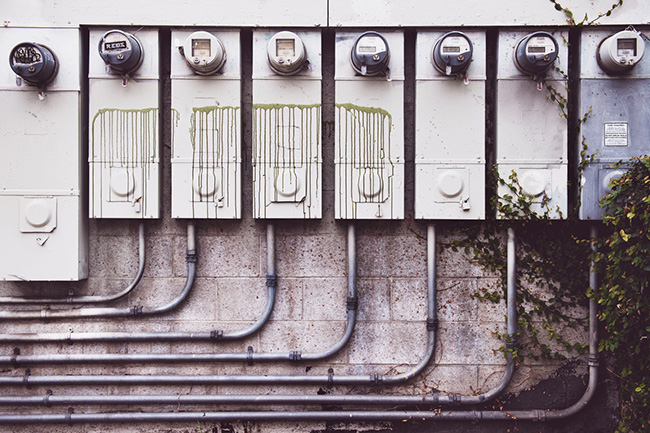

Electrical Maintenance for Your Business

March 29, 2019

Planning a plant relocation and staying within the boundaries of plant relocation deadlines is an effort that presents dozens of challenges to those who want to execute it flawlessly. One flaw in this plan can result in devastating consequences for a company and manufacturing facility in question.

This is why it is of the utmost importance to approach this subject from multiple angles. Today, we’re going to help you understand plant relocation deadlines and how to set them properly so you can stay on schedule.

Research as the Starting Point

You’re not the first, nor the last company relocating an industrial facility. There are already plenty of businesses that have gone through this process. It’s time to open your contact list and call a few numbers, maybe even set up a few meetings.

Look for companies in the same industry with approximately the same scope of operation. During your research, make sure to check how they set deadlines, how it worked for them, what risks they failed to consider, how much did it take to complete the relocation process and other relevant facts.

Devise a Smart Plant Relocation Schedule

Once you know the details about the relocation efforts made by others in your industry, it is the time to start working towards setting plant relocation deadlines. But to do so, you will need to make a relocation schedule and timeline.

Since you won’t be able to move everything in one batch, you will have to decide which pieces to move first. Some of the equipment may have to be reassembled. Take all these time intervals into consideration, including the assembly and installation time, and you will get a crude deadline figure to start working with.

Take Infrastructure into Consideration

Utility connections in the new location are your primary worry. You should acknowledge the fact that industrial electricity is a rather complex and technical topic. This is why you should consult firms that have experience in custom industrial electrical solutions.

It’s extremely important to assess your equipment and facility requirements so that you don’t run into any problems when you try to connect your equipment at the new location. Going through all the infrastructure checkboxes will help you make more accurate deadlines as well.

Packaging and Transit Calculations

Since you are going to move your equipment in batches, you will have to factor in the time required for packaging, loading, unloading, reassembling, and transit when making your plant relocation deadlines equation. Pay attention to the traffic, as it may significantly increase the transit time.

Add Additional Time for Testing

Finally, we come to the testing phase. It’s important to add this to your plant relocation plan, as something might not work properly and you will need extra time to fix it. Adding this time to your schedule will allow you to set more realistic plant relocation deadlines.

As you can see, there is a lot of ground to cover and a lot of factors to consider here. But if you take all the aforementioned tips into consideration, you will be able to make a solid plant relocation plan and set realistic plant relocation deadlines. If you’re looking for industrial-scale electrical assistance along the way, reach out to MSC Electrical today!